The easy way to

future

digitalization

automation

The easy way to

future

digitalization

automation

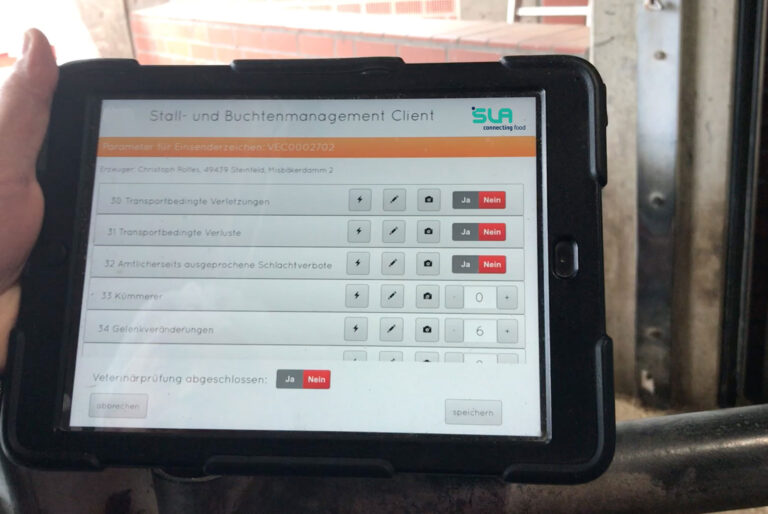

We are SLA

I am robust, powerful and produced with the latest technical standards. I am an industrial computer, made in Germany.

From the daily flood of data in your company, I filter out the information that is important for you to be able to act better, more precisely and more efficiently.

The CLASSIFAI® BOX is the first product of our project group FOODFAIR, based on Artificial Intelligence.

We have received a funding notification from the Federal Ministry of Food and Agriculture for the “GlasSchwein” joint project. The notification was presented by Federal Minister Cem Özdemir to our authorized signatory Michael Brockschmidt, Niko Brand (Brand Qualitätsfleisch GmbH) and Dr. Stefanie Retz (trafo:agrar) at the “Green Week” in Berlin.

Our project FungiAI with the Spanish companies MicrofySystems and LibreFoods geht in die finale Runde: in den letzten Monaten haben wir gemeinsam intensiv an der Entwicklung der neuen Cloud Plattform gearbeitet, die Produzenten dabei unterstützt, ihr Pilzwachstum noch präziser zu überwachen und zu bewerten, um die höchstmögliche Produktqualität zu erreichen. Dank des Mind4Machines funding program waren wir in der Lage, das Projekt innerhalb kürzester Zeit umzusetzen und eine digitale Plattform zu schaffen, die Benutzer dabei unterstützt, KI-basiert Entscheidungen zu treffen und so den Prozess des Pilzwachstums maßgeblich zu optimieren. Wir freuen uns auf die weitere gemeinsame Reise und die stetige Weiterentwicklung der Plattform.

What can we do for you?

Every company has different wishes, questions and requirements for digitalization. Tell us yours. We'll get back to you immediately.

+49 (0) 5431 9480-0

info@sla.de

Newsletter

The SLA newsletter informs you at regular intervals about everything worth knowing about the industry,

innovations and current information from our company.