Karl-Heinz Schlegel

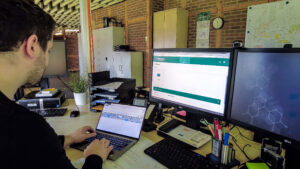

"The control of all sub-areas through the SLA solutions gives us a simplified insight into a highly complex plant. system. We also have an overview of current overview of the current stock levels at all times and minimize minimize the risk of a possible shortage or surplus of goods."

Efrem Gneiding

Project Manager SLA

"Authorized persons have access from anywhere in the world access to what is happening in Badbergen at any time, regardless of whether at the Tönnies home base in Rheda-Wiedenbrück Rheda-Wiedenbrück or in the home office: this creates transparency, simplifies processes and increases productivity."

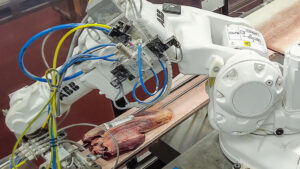

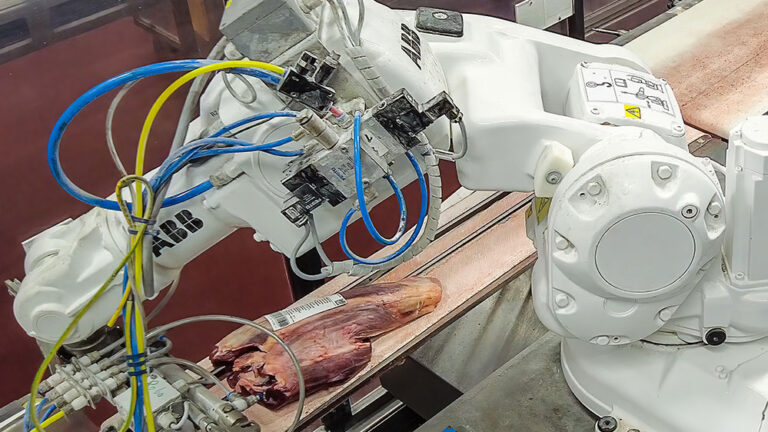

With the aim of expanding the Badbergen production site, which was acquired in 2017, into a modern, highly automated and efficient beef processing center, extensive modernization work was carried out, including the installation of new logistics/storage systems. In order to integrate these into the IT infrastructure and control the logistics processes fully automatically, the Tönnies looking for a modular and flexible digital solution.

Through the use of a fully integrated IT solution for the management and control of all warehouse and picking processes, the Requirements of the company for greater efficiency, sustainability, connectivity and performance. All components from different manufacturers are centrally networked with each other, significantly increasing the level of automation.

And with these products it's possible:

More projects

Hofbräuhaus am Platzl

suppliers