Cross-plant digital networking

at meat producer

Steinemann

Steinemann

Steinemann

Andreas Steinemann

Managing Director Steinemann

"In our production, numerous highly complex processes are controlled and documented. Without a comprehensive IT solution, this would no longer be possible today. SLA comes from the meat industry, knows the specifics and is therefore exactly the right IT partner for us."

Christian Freese

Project Manager SLA

"We don't just want to be a software supplier for our customers, but a digitalization partner at eye level. With our 24/7 premium support, a maximum of individuality and close proximity, both in consulting and in implementation, we do our utmost every day to meet this requirement."

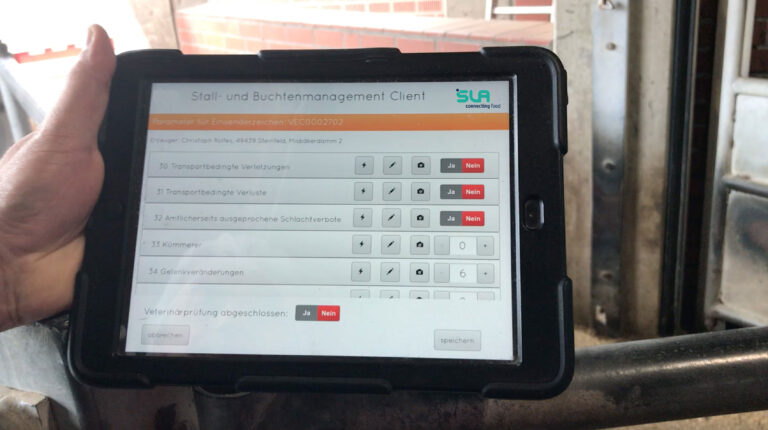

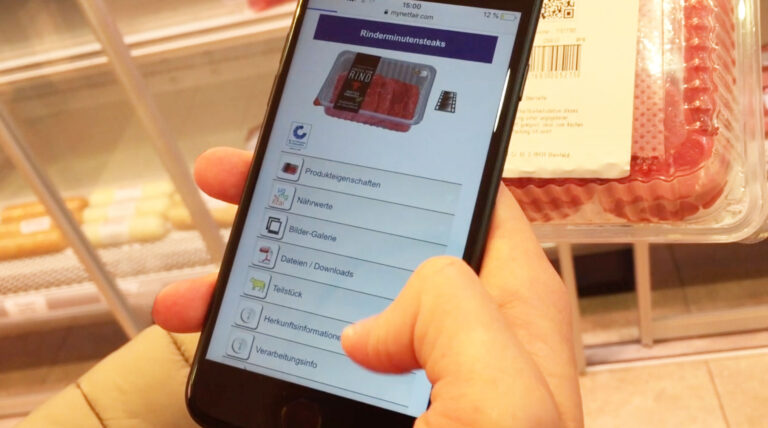

For Steinemann war schnell klar: Die Digitalisierung ist nicht nur ein Trend von kurzer Dauer, sondern muss komplett in die vorhandene Produktionsstruktur einfließen, um Workflows zu automatisieren, Prozesse schneller und flexibler zu gestalten und eine Transparenz und Rückverfolgbarkeit entlang der gesamten Wertschöpfungskette vom Wareneingang bis zum Endverbraucher zu erreichen. Dabei sollten nicht einzelne Insellösungen integriert werden, sondern eine über alle all four plants..

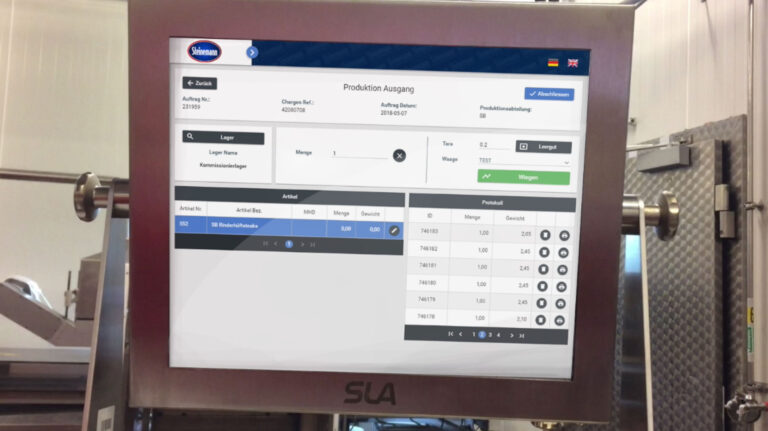

With a mix of the most modern software and hardware solutions, an IT environment was created within a very short time that guarantees Steinemann efficiency, flexibility and complete transparency. Always in view: the active involvement and familiarization of the employees in the new, digital processes.

And with these products it's possible:

More projects

Badbergen

Hofbräuhaus am Platzl

suppliers