Traceability and quality control at ÖFK Österreichische Fleischkontrolle ÖFK Österreichische Fleischkontrolle ÖFK Österreichische Fleischkontrolle

Ing. Stefan Mader, MA

Managing Director ÖFK

"With the SLA web platform, we and the whole of Austria benefit from essential features: traceability of data, origin assurance, central documentation, Austria-wide standardization, simplified data exchange and cost savings through corresponding IT processes. With the joint development of AI solutions, we are also helping to improve the food world even more."

Dr. Gerhard Kronsbein

Software Engineer SLA

As the umbrella organization of the Austrian classification services, the

As the umbrella organization of the Austrian classification services, the ÖFK plays the important role of interface between farmers, slaughterhouses, data customers (e.g. EZG, veterinarians) and government agencies (e.g. AMA, BMSGPK) in Austria. It manages the data flows of classifications, quality programs and ante-mortem and post-mortem inspections and ensures traceability, transparency and quality control. In order to protect the interests of everyone involved in the process and to guarantee complete control, digital support is required.

In the joint project group FOODFAIR solutions based on Artificial Intelligence are also being developed, which are used in various areas of the value chain from pasture to plate and thus improve the food world in the long term.

Today an individually developed Web application networks all those involved in the process on a central platform. As a result, the requirements for high data quality, time and cost-saving processes, complete transparency and traceability are fully met.

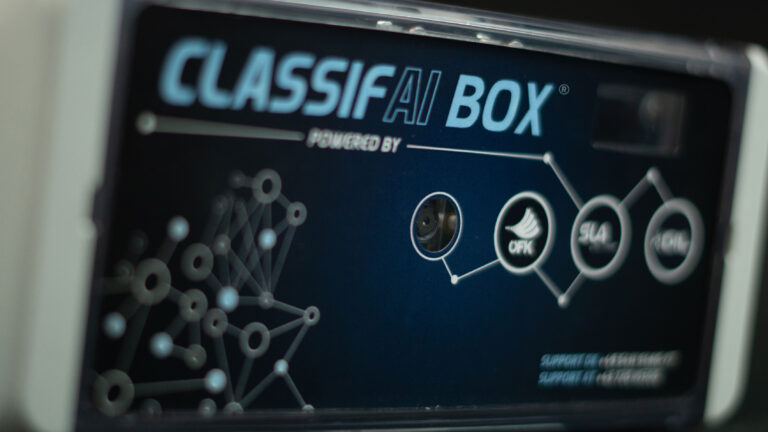

The joint development of the SLA CLASSIFAI® BOXEN (with integrated cameras) has also resulted in the first product in the field of Artificial Intelligence, which is already being used successfully in various projects.

And with these products it's possible:

Through the use of digital solutions, the ÖFK has become one of the most important hubs when it comes to process optimization, transparency and safety in the Austrian meat industry.

More projects

Badbergen

Hofbräuhaus am Platzl

suppliers