Increased efficiency through digitalization at

Food business operator

Hans Kupfer & Sohn Hans Kupfer & Sohn Hans Kupfer & Sohn

Martin Jank

Managing Director Hans Kupfer & Sohn

"Thanks to the digital networking and real-time evaluation of the different packaging lines, our goal for more efficiency was quickly implemented. It also gives us a transparent overview of all steps in the packaging process and leads to a noticeable increase in productivity."

Viktor Herzog

Research & Development SLA

"With our unique Connector technology, we are able to integrate all machines and systems, whether with or without PLC and regardless of the manufacturer or model, into the OEE tool. An extension with additional machines is also possible at any time and without any problems."

In order to meet current challenges such as high energy costs, strict regulations and staff shortages, producers today have to work particularly efficiently. That's why Kupfer went in search of an IT partner to take a close look at the existing production together and to optimize processes with the help of smart digitalization solutions.

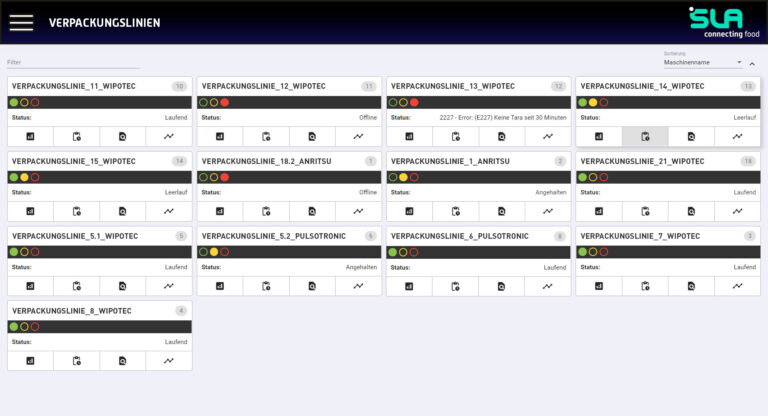

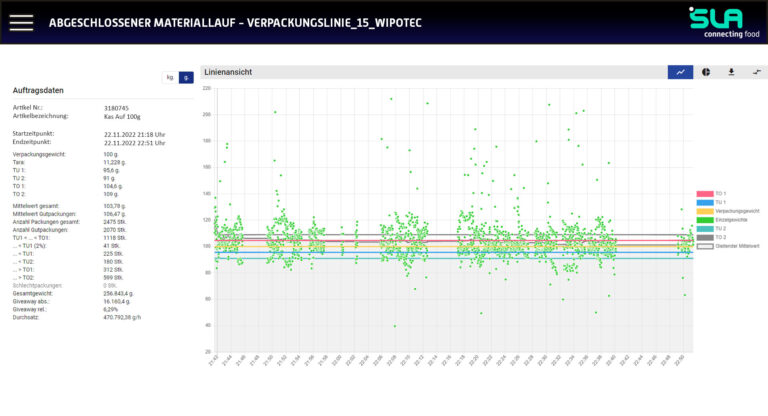

Im ersten Schritt ging es darum, den Verpackungsprozess effizienter zu gestalten. Fast drei Dutzend Verpackungslinien inkl. Checkweigher wurden dafür mittels digital solutions, so that the resulting machine and process data can be collected centrally and fully evaluated. The resulting transparency actively helps to identify weaknesses in the ongoing process and to significantly increase productivity.

And with these products it's possible:

More projects

Badbergen

Hofbräuhaus am Platzl

suppliers