Smart Factory at poultry producer Laemthong Corporation Group Laemthong Corporation Group Laemthong Corporation Group

Axel Arras

Managing Director FPT Asia and partner in the project

"The fully automated processes from incoming goods to outgoing goods, the sustainable iBoxes, the highly efficient raw material warehouse and the comprehensive transparency make Laemthong a pioneer in Thailand and the entire meat industry."

Jörg Brezl

Managing Director SLA

"The digital factory using the example of Laemthong makes it clear that the food industry is more dependent than ever on the use of state-of-the-art software systems in order to meet global challenges with intelligent and sustainable solutions."

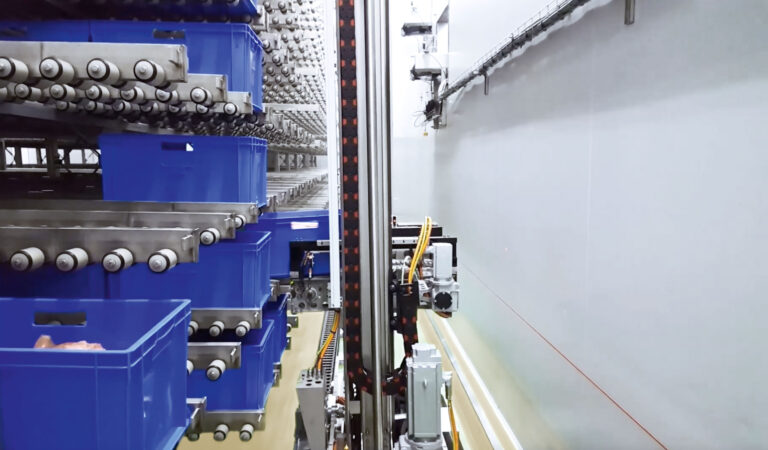

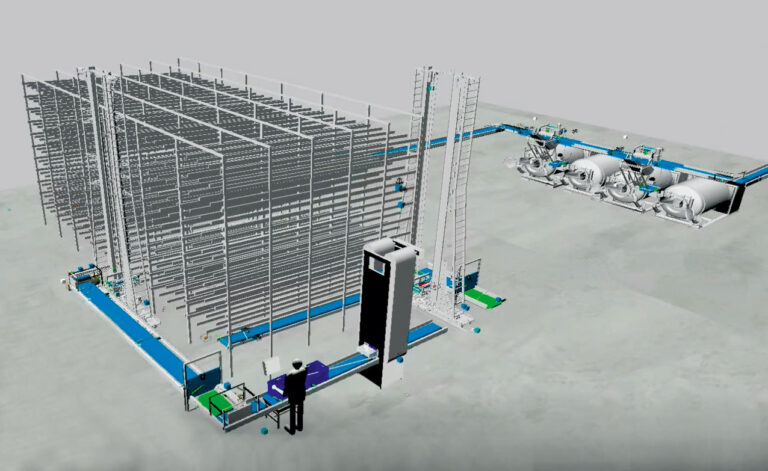

In order to remain competitive in times of advancing digitalization, the Laemthong Corporation Group Laemthong Corporation Group decided to be a pioneer in implementing the world's first Smart Factory in the meat industry. With a reliable IT partner at their side, the aim was to automate processes in production and logistics, to create intelligent and self-communicating machines, and to achieve complete transparency and traceability in the value chain.

With digital solutions from software and hardware, all processes in production and logistics are now networked and run fully automated and with minimal use of personnel.

And with these products it's possible:

From the digital recording of the raw materials in the goods receipt up to the automated packaging and delivery to the customer - with the latest technologies, the Smart Factory now runs almost by itself.

More projects

Badbergen

Hofbräuhaus am Platzl

suppliers