Richard Bard

Managing Director Bard

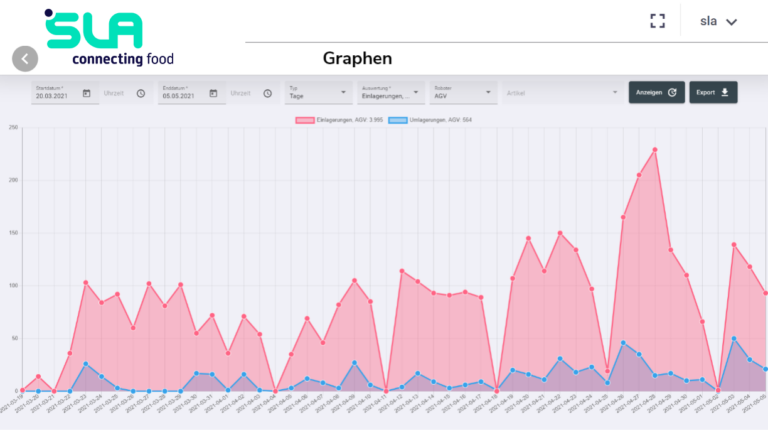

"The integration of the AGV and the networking with the other systems by SLA was so optimal that the resulting, comprehensive data exchange almost completely automates our processes today. This not only saves time and money, but also leads to noticeably more productivity."

Efrem Gneiding

Project Manager SLA

"The project clearly shows what is possible with smart IT. With just a few SLA modules, a process intelligence is created that regulates all work steps almost automatically."

In order to digitally network their 3,500 sqm brand new logistics center, Bard Frische Küche was looking for a suitable digitalization partner. The storage techniques used should be fully integrated and automated in order to obtain transparent controlling over the entire flow of goods.

Through the use of digital software and hardware solutions, a state-of-the-art fresh food logistics system was created at Bard Frische Küche in which Process Intelligence now independently ensures that the entire process chain in storage, picking and shipping is efficiently controlled.

And with these products it's possible:

More projects

Badbergen

Hofbräuhaus am Platzl

suppliers