The CLASSIFAI® BOX is the first product of our project group FOODFAIR, based on Artificial Intelligence. It is used, for example, in:

Animal assessment

For the objective assessment of animal welfare characteristics on pig carcasses and detection of injuries to ears, tail and belly - thus traceability to husbandry and Increase animal welfare

For the objective assessment of animal welfare characteristics on pig carcasses and detection of injuries to ears, tail and belly - thus traceability to husbandry and Increase animal welfare

Classification

For an automated, systemic recording of the carcass and to support the employees in determining the meat quality

For an automated, systemic recording of the carcass and to support the employees in determining the meat quality

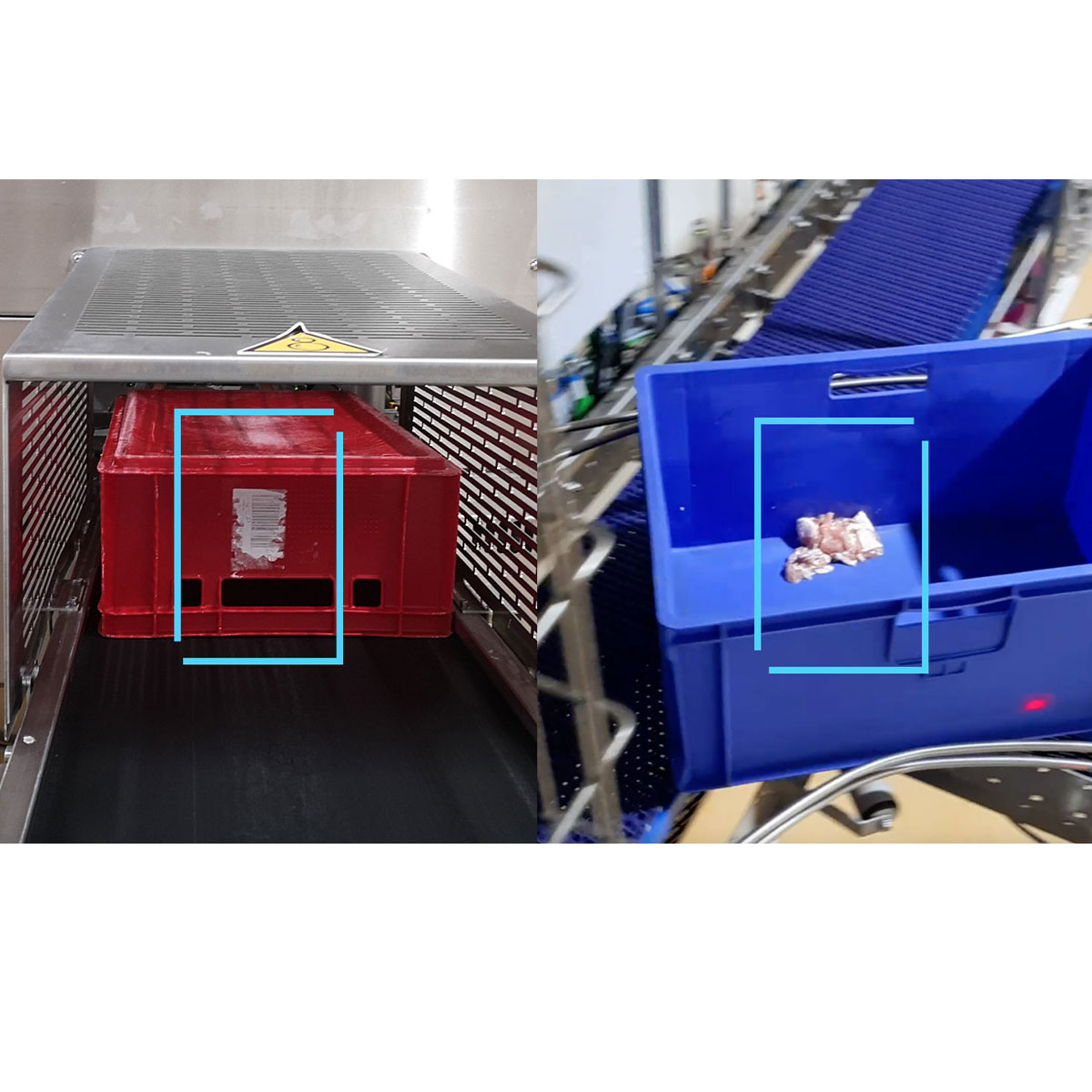

Box washing and identification

For an automated identification of dirt or sticker residues

in und auf Kisten.

Durch die in der blauen

iBox integrierten RFID-Chips

weiß die KI zudem immer, wo

sich welche Box mit welchem

Inhalt befindet

Production planning

of the production volume (incl. the necessary personnel, material and machine requirements), based on historical data and other influences such as weather, public holidays or events, etc.

of the production volume (incl. the necessary personnel, material and machine requirements), based on historical data and other influences such as weather, public holidays or events, etc.

HERE I AM ALREADY successfully successfully successfully IN ACTION

Brand

Digital processes and AI at

slaughterhouse Brand Quality meat

ÖFK

Traceability and quality control at ÖFK Österreichische Fleischkontrolle

Steinemann

Cross-plant digital networking at meat producer Steinemann

Animal assessment

For the objective assessment of animal welfare characteristics on pig carcasses and detection of injuries to ears, tail and belly - thus traceability to husbandry and increasing animal

welfare

For the objective assessment of animal welfare characteristics on pig carcasses and detection of injuries to ears, tail and belly - thus traceability to husbandry and increasing animal

welfare

Classification

For an automated, systemic recording of the carcass and to support the employees in determining the meat quality

For an automated, systemic recording of the carcass and to support the employees in determining the meat quality

Box washing and identification

For an automated identification of dirt or sticker residues in und auf Kisten. Durch die in der blauen iBox integrierten RFID-Chips weiß die KI zudem immer, wo sich welche Box mit welchem Inhalt befindet

For an automated identification of dirt or sticker residues in und auf Kisten. Durch die in der blauen iBox integrierten RFID-Chips weiß die KI zudem immer, wo sich welche Box mit welchem Inhalt befindet

Production planning

Here, AI creates predictive forecasts of the production volume (incl. the necessary personnel, material and machine requirements), based on historical data and other influences such as weather, public holidays or events, etc.

Here, AI creates predictive forecasts of the production volume (incl. the necessary personnel, material and machine requirements), based on historical data and other influences such as weather, public holidays or events, etc.

HERE I AM ALREADY successfully successfully successfully IN ACTION

Brand

Digital processes and AI at

slaughterhouse Brand Quality meat

ÖFK

Traceability and quality control at ÖFK Österreichische Fleischkontrolle

Steinemann

Cross-plant digital networking at meat producer Steinemann